About SureBeam Middle East Co.

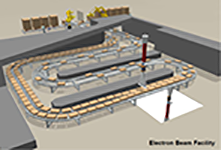

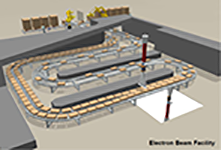

The SureBeam Food and Medical products sterilization facility is

a dual Electron Beam Accelerator. The accelerator Energy is too low

to induce radioactivity in any material, including food.

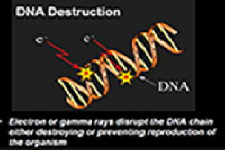

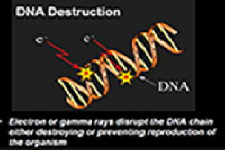

In the E-Beam Mode, electrons are accelerated to near the speed of light using microwaves, into the product breaking the DNA chain of pathogens in the product. Products receive radiant energy from both the upper and lower accelerators so that product flipping is not required and processing can be accomplished in seconds.

In the X-Ray mode, electrons are accelerated to near the speed of light using microwaves into a dense metals which emits x-Rays that pass through the product breaking the DNA chain of pathogens in the product. The product will pass in front of the beam and then be rotated 1800 to make a pass on its side. X-Ray is primary used with bulky, non uniform, high density products.

In the E-Beam system, utilizes a dual conveyance system to move

the product in and out of the process chamber. All LINACS and

controls are controlled with Allen Bradley Programmable Logic

Control (PLC) software. The software along with automatic control

system enables the electronic pasteurization process to be virtually

automated and very tightly controlled with few staffing

requirements.

SureBeam Middle East facility is first of its kind and the state-of-the-art facility unavailable in the Middle East, and now is in fully commercial operation and is one of the most promising food safety technologies of the 21st century–food irradiation with electron beam technology.

The Irradiation Technology has an important role to play in the Kingdom of Saudi Arabia, in the production of safe, higher quality foods, and a more plentiful food supply by extension of shelf life and controlling pests and pathogens in food. Other processes such as chemicals and heat treatments can kill insects, moulds and microorganisms, but chemical leaves residues and heating food, changes its texture, color, and flavor and converts it into cooked products. Irradiation, on the other hand, achieves its effects without significantly raising the temperature of food, leaving it closer to the unprocessed state.

E-beam exposure is becoming increasingly popular as a lower cost alternative for the sterilization of medical devices.

Electron beam sterilization (e-beam sterilization) is a commercially successful technology for sterilizing a variety of disposable medical devices with a wide range of densities.

The e-beam inactivates microorganisms either by causing microbial death as a direct effect of the destruction of a vital molecule of by an indirect chemical reaction. This is the same mechanism as in gamma irradiation, and the dose required is the same.

Advanced electronics precisely control the use of electrons in the sterilization of medical devices. For many materials, e-beam processing results in less material degradation than with gamma irradiation.

We typically sterilize medical products in the original shipping containers, saving you time and maintaining package integrity. As the beam is scanned through the product, the electrons interact with materials and create secondary energetic species, such as electrons, ion pairs, and free radicals. These secondary energetic species are responsible for the inactivation of the microorganisms as they disrupt the DNA chain of the microorganism, thus rendering the product sterile.

Approximately 50% of all single use medical devices manufactured in the world today are sterilized with ionizing energy from electron sources. E-beam, a proven technology that was introduced over 50 years ago, is routinely used to sterilize very large quantities of disposable medical devices at very low cost.

E-beam uses ionizing energy in the form of accelerated electrons. In ionization, atomic electrons are removed from molecules (thus damaging the DNA). Such ionization is lethal to all forms of life when a sufficient dose is absorbed. 25 kGy is a typical sterilization dose.

SME, E-Beam technology does not leave chemical residues in the products being sterilized. Our sterilization sources are electric-powered and therefore do not entail the handling, licensing, shipping, disposal or use of radioisotopes.

chemical residues in the products

E-beam uses ionizing energy in the form of accelerated electrons. In ionization, atomic electrons are removed from molecules (thus damaging the DNA). Such ionization is lethal to all forms of life when a sufficient dose is absorbed. 25 kGy is a typical sterilization dose.

SME, E-Beam technology does not leave chemical residues in the products being sterilized. Our sterilization sources are electric-powered and therefore do not entail the handling, licensing, shipping, disposal or use of radioisotopes.

Connect with us

+966 (11) 4984462

faq@smebeam.com